INSTRUCTIONS FOR DURAMAX BOOST LEAK TESTER KITS

Duramax 6.6L 30 PSI Base Kit, Duramax 6.6L 60 PSI With Extension Boost Leak Tester Kit, & Duramax 6.6L 60 PSI With Regulator Boost Leak Tester Kit

Thank you for your purchase!

If you have any questions about this product feel free to reach out to Turbo Boost Leak Testers directly at support@turboboostleaktesters.com or call/text any time at 248-403-8512

Package Contents: Duramax 6.6L 30 PSI Base kit

- (1) 2.5” Billet CNC machined aluminum end cap featuring an anti-slip bead and machined grooves for grip high pressure testing

- (1) 30 PSI Boost Gauge

- 2.5” Stainless Steel T-bolt Clamp

- Air fitting

Package Contents: Duramax 6.6L 60 PSI With Extension

- (1) 2.5” Billet CNC machined aluminum end cap with ¼” NPT Air fitting

- (1) 60 PSI Boost Gauge and stainless steel shut off ball valve

- (1) Extension hose with quick release connection to boost leak tester

- (1) Teflon Tape for assembly

- End cap features an anti-slip bead and machined grooves for grip high pressure testing

Package Contents: Duramax 6.6L 60 PSI Regulator Kit

- (1) 2.5” Billet CNC machined aluminum end cap with ¼” NPT Air fitting

- (1) 150 PSI Pressure Regulator

- (1) 60 PSI Boost Gauge and stainless steel shut off ball valve

- (1) Extension hose with quick release connection to boost leak tester

- (1) Teflon Tape for assembly

- End cap features an anti-slip bead and machined grooves for grip high pressure testing

This Boost Leak Tester is designed to work on ALL Duramax 6.6L engines (except L5P-We sell a specific kit for L5P)

- LB7, LLY, LBZ, LMM

- Chevy Silverado, GMC Sierra 2500HD 3500HD, Express, Savana, Topkick, Kodiak, 2001 - 2004 LB7, 2004.5 - 2010 LLY LBZ LMM, 2010-2011 LGH, 2011 - 2016 LML

- Also works with all aftermarket 3” hot pipes using the stock turbo

Using this tester kit:

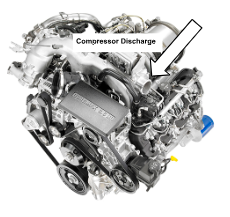

Remove the hose off the turbo compressor discharge and slip the tester inside the hose. This hose is what connects the turbo outlet to the hot pipe leading to the intercooler cac. Clamp the tester inside the hose, and use your air compressor to test up to 60 PSI and detect any leaks in the WHOLE charge pipe path the turbo NORMALLY pressurizes while boosting- including the hot & cold pipes, intercooler CAC, Y-bridge, EGR, and all clamped connections with no need to cap off the other end. You will be able to listen for any leaks.

The 5 ft extension hose makes it easy to control pressure without leaning over the engine bay.

Q&A: “Why dont i just test at the inlet?”

Our response to this is that it is much more complicated to test at the turbo inlet. The plastic inlet pipe has PCV connections to route to the valve covers and these will need to be blocked or the test pressure will go into the charge pipes AND in the motor’s crank case, this is not desirable as it puts a large stress on all the oil seals. There is also more piping and connections to remove when testing pre turbo. This boost leak tester installs on the compressor outlet/discharge and will find leaks in every single connection after the turbo, which is where the leaks are at, the wearable joints and connections that break down over time. The turbos compressor cover is not an area of concern especially if it is stock.

Q&A: “I cant build pressure OR the gauge reads 0 PSI”

Check the EGR valve, there is a very good chance it is not closing completely, dumping all the test pressure into the exhaust.

Tips during testing:

- Always wear safety glasses and face protection. Stand clear from the tester when under pressure as it or any other component may blow off during pressurization.

- Start with a low pressure on your compressor and work your way up. The largest leaks will be found first, fix them and retest to find the next smaller leak.

- A good starting pressure is 10 PSI and work up to 20 PSI or 30 PSI, or what you normally boost when driving.

- If your system is filling too slowly, increase the pressure on your compressor outlet, but be cautious not to over pressurize the charge pipes. The boost gauge on the tester will indicate what the charge pipe pressure is.

- Soapy spray can be used to identify smaller leaks that may be hard to hear.

- If the system is not filling at all, then there is a leak large enough or something is disconnected.

- NO - you do not need to cap off the other end. The charge pipes and engine will hold the pressure and pressure will not escape through the engine into the exhaust.

After fixing all obvious leaks, use the shut off valve and keep the pressure trapped in the system to evaluate how well the system holds. About 1 psi for every second or two is normal. At higher pressure, for example, 20PSI it will drop faster then start to slow down as the pressure falls to 0psi.

Purge all the air first before removing the tester

Now enjoy making boost with confidence!

Legal Disclaimer

TURBO BOOST LEAK TESTERS, INC., AND/OR ANY OF ITS DIRECTORS, EMPLOYEES, AND AFFILIATES ARE NOT RESPONSIBLE FOR ANY INJURY, DEATH OR PROPERTY DAMAGE ASSOCIATED WITH THE PURCHASE AND USE OF ANY PRODUCT(S) PURCHASED FROM TURBO BOOST LEAK TESTERS, INC. THE PURCHASER, ASSUMES SOLELY THE RESPONSIBILITY OF ENSURING THAT ALL SAFETY PRECAUTIONS, RESTRICTIONS AND WARNINGS ARE ADHERED TO. MOREOVER, IT IS THE RESPONSIBILITY OF THE PURCHASER TO ABIDE BY ALL STATE, LOCAL AND FEDERAL LAWS WHEN USING ANY PRODUCT(S) PURCHASED FROM TURBO BOOST LEAK TESTERS, INC. THE PURCHASER AGREES TO INDEFINITELY AVOID ANY MISUSE OF THE PRODUCT AND TURBO BOOST LEAK TESTERS, INC. WILL BE NOT BE HELD LIABLE FOR INDIRECT, INCIDENTAL, AND/OR CONSEQUENTIAL DAMAGES CAUSED BY THE PURCHASE, INSTALLATION, AND/OR USE OF THE PRODUCT. YOUR PURCHASE FROM TURBO BOOST LEAK TESTERS, INC. IS YOUR UNDERSTANDING AND ACCEPTANCE OF THE ABOVE DISCLAIMER. SAFETY WARNING WHEN USING COMPRESSED AIR, OBJECTS MAY EXPLODE AND ACT AS PROJECTILES THAT MAY CAUSE SERIOUS PERSONAL INJURY OR DAMAGE. THEREFORE, FOR YOUR OWN SAFETY, WHEN USING COMPRESSED AIR ALWAYS WEAR APPROVED ANSI (AMERICAN NATIONAL STANDARDS INSTITUTE) SAFETY GLASSES OR GOGGLES. MOREOVER: WHEN PRESSURIZING THE BOOST LEAK TESTER ALWAYS STAY CLEAR OUT OF THE LINE OF FIRE. BE AWARE OF OTHER COMPONENTS ON THE ENGINE THAT WILL BE PRESSURIZED DURING THE BOOST LEAK TEST. THESE OTHER COMPONENT MAY ALSO EXPLODE AND ACT AS PROJECTILES. TO PREVENT ENGINE DAMAGE ALWAYS SET YOUR AIR COMPRESSOR TO A LOW OUTLET PRESSURE SETTING TO AVOID ACCIDENTAL OVER CHARGING. DO NOT EXCEED THE NORMAL BOOST LEVEL THE VEHICLE IS CALIBRATED TO. ALWAYS REMOVE THE OIL CAP TO VENT EXCESS PRESSURE IN THE CRANK CASE. THIS PREVENTS POTENTIAL ENGINE OIL SEAL DAMAGE. PLEASE AVOID ANY MISUSE OF THE PRODUCT AND ADHERE TO ALL SAFETY PRECAUTIONS AND WARNINGS WHEN USING THIS PRODUCT.